Future-Proof Your Manufacturing: Why Cutting-Edge CAM Software is a Game-Changer

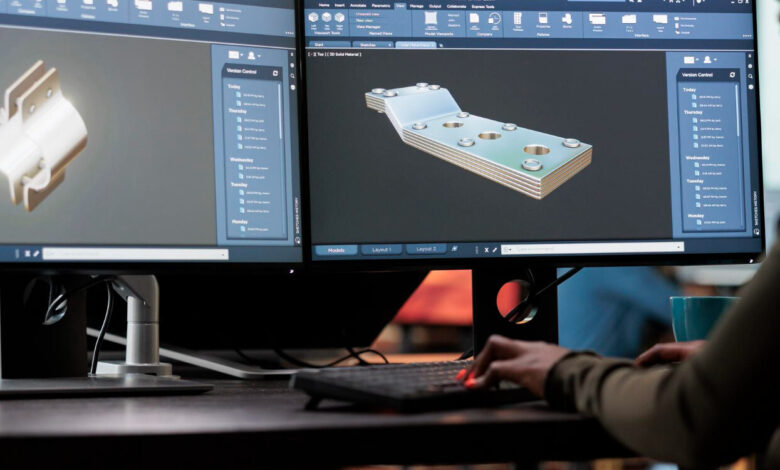

The landscape of manufacturing has been radically transformed by technological advancements, particularly through the integration of Computer-Aided Manufacturing (CAM) software. Manufacturers are now equipped with tools that promise increased efficiency, precision, and adaptability in a rapidly evolving industry.

Streamlining Production Processes With Advanced CAM Solutions

Today’s manufacturing sector is characterized by its pursuit of leaner, more efficient production processes. Advanced CAM solutions are at the forefront of this quest, edging out traditional methods with their precision and speed. These software systems automate many aspects of production, including tool selection and path generation, resulting in more efficient use of resources and labor.

With sophisticated algorithms, CAM software optimizes machining processes, reducing cycle times and enhancing throughput. This optimization ensures that manufacturers can achieve more in less time, translating into higher profitability and better resource management.

What’s more, the integration of CAM solutions often entails better communication across production teams. Digital designs and machine instructions can be easily shared and accessed, ensuring everyone works from the same, accurate data set. Manufacturing errors decrease as a result, boosting overall quality control.

As custom orders and small batch production become more commonplace, CAM’s flexibility becomes increasingly valued. Manufacturers can switch between production modes with minimal downtime, allowing them to maintain a diverse product offering and adapt quickly to specialized projects.

Enhancing Precision and Reducing Waste: The Tangible Benefits of CAM Technology

The precision afforded by advanced CAM technology is a significant step forward in terms of product quality and consistency. Manufacturers can now execute designs to exact specifications, ensuring that each part meets rigorous standards. This level of accuracy helps in minimizing post-production modifications and rework, leading to a smoother workflow and a better end product.

Waste reduction stands as another key benefit of CAM software integration. By optimizing material use and reducing the occurrence of errors that lead to scrap, companies conserve resources and reduce their environmental footprint. Such operational efficiency not only cuts costs but also aligns with the growing global emphasis on sustainable manufacturing practices.

Investments in CAM technology also translate into savings over time. As manufacturers reduce waste and improve product quality, they inevitably see a return on their investment through customer satisfaction and retention. High-quality, reliable products become synonymous with the brand, helping to establish a competitive edge.

Moreover, the flexibility of ESPRIT CAM allows manufacturers to quickly adapt tool paths and processes to accommodate new materials or design changes. This agility ensures they can stay ahead of industry trends without incurring costly delays or significant retooling expenses.

Integrating CAM Software with IoT and AI for Smart Manufacturing

The combination of CAM software with the Internet of Things (IoT) and Artificial Intelligence (AI) marks the advent of truly smart manufacturing. This integration results in a connected network of machines that communicate with each other, providing real-time feedback and adjustments to optimize production without human intervention.

With IoT sensors, manufacturers can monitor machinery performance and predict maintenance needs. When CAM software is involved, it can preemptively adjust tasks to prevent downtime. This interfacing between software and hardware highlights the potential of predictive analytics in manufacturing—minimizing disruptions and prolonging the lifespan of valuable equipment.

AI further elevates the capabilities of CAM by introducing intelligent decision-making processes. It can analyze vast quantities of data to improve production strategies. For instance, machine learning algorithms can refine tool paths, reducing wear on tools and extending their life while enhancing product quality.

Preparing for the Future: Investing in CAM Software for Long-Term Success

Adopting CAM software is not just a strategic move for immediate efficiency gains; it’s an investment in the future of manufacturing. It positions companies to be agile and responsive to the changing demands of the market and new technological developments. By staying at the forefront of manufacturing technology, businesses prepare themselves to face whatever challenges and opportunities the future holds.

A focus on software-driven manufacturing also encourages a culture of continuous improvement. As CAM technology evolves, opportunities for further optimizations and enhancements present themselves. This iterative approach to manufacturing excellence promotes a mindset of perpetual innovation that’s essential for long-term success.

Investing in advanced CAM systems today ensures manufacturers are well-equipped to capitalize on emerging trends like mass customization, environmentally sustainable production, and the push for comprehensive digital integration. CAM software is the crucial tool that will carve the path towards these advances.

Altogether, the growth and development of CAM software represent a seismic shift in manufacturing, setting a new benchmark for efficiency, quality, and innovation. Manufacturing’s future lies in embracing these digital tools, and the companies that recognize this will lead the way in the industry’s evolution.