The Advantages of Using Rotary Screw Compressors for Your Business

In today’s competitive industrial landscape, choosing the right equipment can significantly impact operational efficiency and cost-effectiveness. For many businesses, compressed air systems are essential, and selecting the appropriate compressor type is a critical decision. Among the various options available, the rotary screw compressor stands out for its reliability and performance. Whether for heavy-duty industrial use or more refined applications, understanding the potential of these systems can be a game-changer for your business. Below, we delve into the distinct advantages that rotary screw compressors can offer.

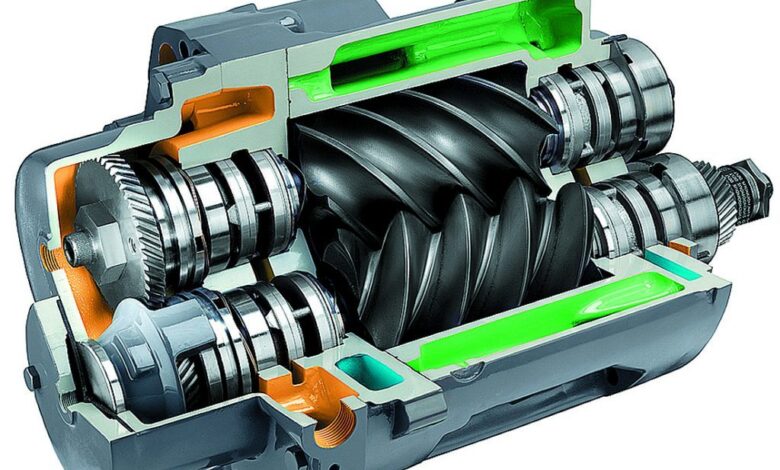

Understanding Rotary Screw Compressors and Their Operational Efficiency

Rotary screw compressors operate using two interlocking screws that compress air efficiently as it moves through the system. Known for their ability to run continuously at full load, they provide a steady air supply essential for industrial operations. Their efficiency is enhanced by capacity control systems and variable speed drives (VSDs), which adjust motor speed to match airflow demand and reduce energy waste.

With fewer moving parts, these compressors require minimal maintenance, ensuring reliable performance and reduced downtime. Their design often integrates aftercoolers and oil separators, producing cleaner, drier air that maintains product and process quality while supporting consistent operational efficiency.

Enhanced Energy Savings with Rotary Screw Compressor Technology

Energy consumption plays a major role in the operational costs of businesses using compressed air systems. Rotary screw compressors help reduce these costs through efficient design and continuous operation at a 100% duty cycle, preventing energy loss from frequent starts and stops. Their variable speed drives (VSDs) adjust power use according to air demand, leading to lower electricity expenses.

Heat recovery systems capture the heat generated during compression for water or space heating, minimizing waste and carbon output. These compressors also feature efficient engine designs with low specific power, meaning less electricity is needed to produce compressed air, providing significant long-term energy savings.

Durable and Low-Maintenance: Long-term Benefits for Businesses

Rotary screw compressors are known for their durability, offering long-term stability and cost savings for businesses. Their robust build and minimal moving parts reduce the risk of mechanical failure, making them ideal for continuous industrial operations. Maintenance demands are lower, leading to less downtime and labor costs.

The simple design allows easy access for component replacement, improving efficiency. Built-in cooling and lubrication systems help control temperature and friction, extending the equipment’s lifespan. Many models also include advanced monitoring systems that predict maintenance needs, enabling proactive servicing and preventing unexpected breakdowns, which helps maintain consistent performance and a better return on investment.

Versatility in Applications: How Rotary Screw Compressors Serve Various Industries

Rotary screw compressors offer exceptional versatility across industries, from manufacturing to healthcare. Their ability to produce high volumes of compressed air makes them ideal for large-scale operations such as powering pneumatic tools in factories and construction sites that require continuous airflow. They are also suited for precision industries like pharmaceuticals, food processing, and electronics manufacturing, where oil-free models deliver clean, contaminant-free air.

With various capacities and designs available, these compressors can be customized for both portable and stationary applications. The automotive industry also relies on its consistent performance for tasks such as painting and assembly, ensuring reliability and precision in demanding environments.

Noise Reduction and Improved Work Environment with Rotary Screw Systems

Excessive noise in workplaces can reduce productivity and affect employee health. Rotary screw compressors are quieter than reciprocating types due to their enclosed design and smoother operation, creating a safer and more comfortable environment. Their reduced noise levels also help companies comply with occupational health and safety regulations, supporting a sustainable work culture.

Built-in soundproofing features, such as attenuation materials and enclosures, minimize noise impact on surrounding areas, especially near residential zones. Lower noise levels enhance communication and collaboration among employees, fostering better teamwork and higher morale that contribute to improved productivity and a more efficient workplace.

Overall, the benefits of incorporating a rotary screw compressor into your business are numerous and impactful. From enhanced energy savings and reduced noise to durability and versatility, these compressors offer a range of advantages that can support a variety of industrial applications. By investing in a rotary screw compressor, businesses place themselves in an excellent position to improve efficiency, cut costs, and maintain a reliable and productive operation.